How Aluminum Castings contribute to cost savings in production

Wiki Article

The Duty of Aluminum Casting ahead of time Lasting Production Practices

Aluminum casting offers as an essential aspect in promoting lasting manufacturing methods. Its ability to generate high-grade components with a decreased environmental impact is amazing. The procedure not just supports energy efficiency however also greatly boosts recyclability. Nevertheless, challenges continue to be in completely recognizing its potential. Checking out the developments in aluminum casting innovation could expose solutions that straighten making with sustainability goals. The ramifications of these developments are worth considering.Understanding Aluminum Casting and Its Process

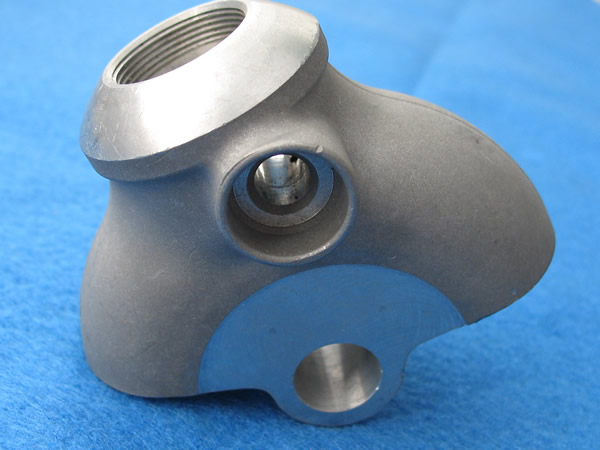

Although aluminum casting has been a fundamental procedure in making for decades, its significance proceeds to expand in numerous markets as a result of its versatility and performance. This process entails putting molten aluminum right into mold and mildews to produce detailed shapes and parts, making it excellent for creating light-weight yet sturdy items. The aluminum casting process can be categorized right into a number of methods, including sand casting, pass away casting, and financial investment casting, each offering unique advantages fit to certain applications.Throughout the casting procedure, aluminum is warmed to its melting factor, allowing it to stream conveniently right into molds that define the final shape. Once cooled, the aluminum strengthens, leading to a strong and precise element. The capacity to produce complex geometries with marginal waste underscores aluminum casting's function in contemporary manufacturing - Aluminum Castings. As sectors seek ingenious options, recognizing this procedure comes to be necessary for maximizing production and meeting the needs of an evolving market

Ecological Benefits of Aluminum Casting

As markets increasingly prioritize sustainability, the environmental benefits of aluminum casting come to be much more noticable. One considerable advantage is the material's recyclability; aluminum can be recycled repetitively without degrading its quality. This lowers the amount of waste sent to landfills and reduces the need for virgin materials, conserving natural sources. In addition, the aluminum casting procedure creates less greenhouse gas emissions compared to other steel casting techniques, contributing to reduced total environmental effect.An additional benefit depends on the lightweight nature of aluminum, which results in sustain performance in transportation applications. By using aluminum elements, manufacturers can reduce lorry weight, resulting in reduced gas intake and emissions throughout procedure. Improvements in aluminum casting modern technologies have led to a reduction in harmful waste manufacturing, enhancing total eco-friendly security. Jointly, these elements setting aluminum casting as a principal in advertising lasting manufacturing techniques and conference ecological objectives across numerous markets.

Power Performance in Aluminum Manufacturing

Energy effectiveness plays a vital function in aluminum manufacturing, substantially influencing general sustainability. By embracing ingenious casting strategies and incorporating renewable resource sources, suppliers can attain reduced energy intake throughout the production procedure. This shift not just reduces functional expenses however additionally contributes to a more eco-friendly sector.

Lowered Power Consumption

While the aluminum manufacturing industry has actually commonly been energy-intensive, current improvements have greatly enhanced energy effectiveness throughout the manufacturing procedure. Advancements in smelting technology and the fostering of high-efficiency heating systems have actually substantially reduced energy usage. These improvements permit producers to utilize less energy each of outcome, lessening greenhouse gas emissions and reducing functional expenses. In addition, the combination of eco-friendly energy sources into production facilities further contributes to minimized dependence on fossil gas, promoting sustainability. Executing sophisticated insulation materials and maximizing warm recuperation systems also plays an essential function in optimizing power performance. Because of this, the aluminum industry is making significant strides toward lowering its total ecological impact while satisfying the boosting need for lasting practices in production.Ingenious Casting Techniques

Ingenious casting methods are transforming the aluminum production landscape, boosting both effectiveness and sustainability. Advanced methods such as die casting and financial investment casting minimize material waste and improve dimensional accuracy, leading to lowered power usage throughout the production process. Strategies like fast solidification and semi-solid handling permit far better control over metallurgical buildings, resulting in light-weight and high-strength elements. Furthermore, the implementation of computer system simulations and automation in casting processes maximizes cycle times and reduces defect prices. These developments not only simplify manufacturing however likewise add to the round economic situation by allowing the recycling of aluminum scrap into premium products. As a result, the aluminum market is poised to fulfill growing demands while adhering to sustainable manufacturing methods.Renewable Energy Assimilation

A significant shift in the direction of renewable resource combination is reshaping power effectiveness in aluminum production. This modification includes utilizing solar, wind, and hydropower sources to decrease dependence on fossil gas, substantially lowering carbon emissions. Facilities are significantly embracing energy-efficient modern technologies, such as advanced electrolytic procedures, which enhance power intake throughout aluminum production. By harnessing sustainable energy, browse around here makers not only lower functional costs but likewise boost their sustainability accounts. Furthermore, wise grid innovations facilitate the smooth combination of eco-friendly resources, enabling for even more steady energy materials. As the industry welcomes these innovations, the aluminum sector is positioned to lead in lasting practices, demonstrating a dedication to ecological stewardship while fulfilling increasing worldwide demand for lightweight, high-performance products.The Recyclability of Aluminum and Its Effect

Aluminum's recyclability supplies considerable benefits in sustainable production, allowing for infinite recycling without loss of top quality. This building not just minimizes waste yet additionally enhances power performance throughout the recycling procedure. Consequently, the effect on both the setting and production prices is profound, making aluminum a favored product in eco-conscious markets.Infinite Recycling Prospective

Numerous materials lose high quality via reusing processes, aluminum stands out due to its unlimited recyclability, which considerably adds to sustainable production practices. This special characteristic enables aluminum to be recycled repetitively without deteriorating its homes, making it an important source in numerous sectors. The lifecycle of aluminum starts over again with each recycling effort, preserving basic materials and reducing waste. This not only minimizes the environmental effect however likewise fosters a circular economy where aluminum can be recycled many times. The high demand for recycled aluminum further emphasizes its relevance in lasting manufacturing, as it boosts resource performance and advertises a green technique to manufacturing. Inevitably, the boundless reusing potential of aluminum plays a considerable function beforehand lasting techniques across sectors.

Energy Effectiveness Conveniences

Considerable energy financial savings are recognized with the recycling of aluminum, highlighting its role in sustainable manufacturing. Recycling aluminum calls for just 5% of the power needed to produce brand-new aluminum from resources. This substantial decrease in power usage translates right into reduced greenhouse gas exhausts, adding to environmental sustainability. The power effectiveness of aluminum recycling not just preserves sources however likewise reduces operational expenses for manufacturers, making it a financially feasible choice. Furthermore, the procedure of recycling aluminum can be integrated into existing assembly line without substantial disruption, improving overall efficiency. As markets progressively prioritize sustainability, the recyclability of aluminum settings it as a principal ahead of time energy-efficient manufacturing techniques, cultivating a round economic climate and advertising liable source management.Difficulties Encountering Aluminum Casting in Lasting Practices

While the aluminum casting industry has actually made strides in the direction of lasting methods, numerous obstacles continue to be that impede its progress. One considerable issue is the high power usage related to typical casting techniques, which often relies upon fossil gas. This dependancy not only raises functional prices however additionally adds to greenhouse gas emissions. In addition, the recycling procedure for aluminum can be ineffective, bring about material loss and raised waste. An additional obstacle is the Click This Link limited schedule of lasting raw materials, as sourcing recycled aluminum can be tough and pricey. Furthermore, regulatory pressures and varying ecological requirements throughout areas complicate conformity efforts, making it testing for business to embrace consistent sustainable methods. Ultimately, labor force training stays poor, with lots of workers doing not have the essential abilities to implement ingenious, environmentally friendly methods in casting procedures. Addressing these difficulties is vital for the aluminum casting sector to totally recognize its capacity in lasting production.Innovations in Aluminum Casting Technology

To conquer the difficulties faced in sustainable methods, the aluminum casting industry is witnessing a wave of technologies targeted at enhancing effectiveness and decreasing environmental influence. Advanced casting methods, such as 3D printing and die casting, are being adopted to lessen material waste and boost accuracy. These modern our website technologies make it possible for suppliers to create complex geometries with less aluminum, therefore saving sources.In addition, the integration of recycling techniques, including closed-loop systems, helps with making use of scrap aluminum, greatly minimizing power usage contrasted to key aluminum production. Boosted mold and mildew designs and coverings are also contributing to sustainability by enhancing thermal efficiency and minimizing discharges during the casting process.

Additionally, automation and wise production technologies are being applied to enhance production processes, causing lowered cycle energy and times use. Collectively, these developments stand for a considerable shift towards more lasting practices within the aluminum casting market, straightening with wider environmental objectives.

Future Prospects for Sustainable Manufacturing With Aluminum Casting

As the demand for sustainable manufacturing practices intensifies, the aluminum casting industry is poised to play a critical duty fit a greener future. The market is significantly adopting recycling processes that considerably lower waste and energy consumption, straightening with international sustainability goals. Advancements such as low-energy casting methods and the usage of recycled aluminum not only lessen carbon impacts but additionally improve the general performance of production.

As industries look for to follow more stringent environmental guidelines, the aluminum casting industry stands all set to supply lasting services, positioning itself as an essential player in the change in the direction of green manufacturing practices in numerous markets, including automobile and aerospace.

Frequently Asked Concerns

Just How Does Aluminum Casting Compare to Various Other Metal Casting Methods?

Aluminum casting typically supplies advantages such as reduced melting factors and premium recyclability contrasted to other metal casting approaches. Its lightweight nature and superb deterioration resistance additionally improve its appeal in numerous manufacturing applications.What Industries Advantage A Lot Of From Aluminum Casting?

Different sectors, consisting of automobile, aerospace, and durable goods, substantially gain from aluminum casting - Aluminum Castings. This technique's lightweight, corrosion-resistant buildings enhance item efficiency while permitting for complex designs, making it an appealing option for makers seeking performance and advancementCan Aluminum Casting Be Used for Complex Designs?

Aluminum casting can effectively fit complex layouts because of its versatility and ability to create elaborate shapes. This process makes it possible for manufacturers to produce light-weight, durable components ideal for different applications throughout different markets, enhancing innovation and effectiveness.What Is the Life-span of Aluminum Cast Products?

The lifespan of aluminum cast products commonly ranges from several years to over a century, depending on elements such as ecological problems, maintenance, and the specific application. Toughness makes them appropriate for different long-term usages.How Does Aluminum Casting Influence Job Production in Production?

Aluminum casting considerably adds to job production in production by fostering competent labor chances, supporting neighborhood economic situations, and encouraging technical improvements. This process not just enhances manufacturing efficiency however also advertises workforce development and training efforts.Report this wiki page